How Welding Inspection Gilbert Arizona Can Boost Your Construction and Production Processes

How Welding Inspection Gilbert Arizona Can Boost Your Construction and Production Processes

Blog Article

A Comprehensive Guide to Welding Inspection: Understanding Standards, Techniques, and Finest Practices for Quality Control

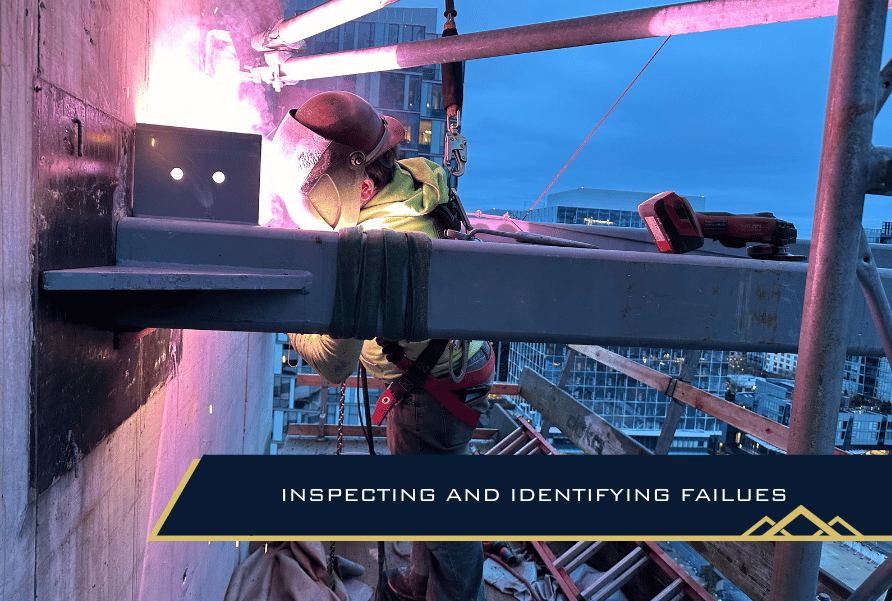

Welding assessment plays a critical function in making sure the architectural stability and security of bonded elements, necessitating a comprehensive understanding of market requirements such as those developed by AWS and ASME. Numerous inspection techniques, including ultrasonic and visual screening, are used to find prospective flaws that could jeopardize high quality. Executing ideal methods can substantially enhance functional dependability and foster count on amongst customers. Welding Inspection Gilbert Arizona. As we check out these crucial components, it becomes evident that the ramifications of welding assessment expand far beyond compliance, welcoming a more detailed assessment of how these processes form industry standards and techniques.

Importance of Welding Assessment

Welding examination plays a crucial role in guaranteeing the integrity and security of bonded structures. It is an important process that validates that welds adapt to predefined specifications, which is vital in different markets, consisting of building and construction, automobile, and aerospace. By conducting thorough inspections, possible issues such as cracks, insufficient fusion, and porosity can be recognized early, protecting against tragic failures that might bring about mishaps or costly fixings.

The relevance of welding examination prolongs past simple conformity with regulations; it also cultivates depend on with stakeholders. Clients and governing bodies anticipate guarantee that the frameworks they rely on are developed to endure operational stresses. Moreover, reliable welding examination practices add to long-term sturdiness and performance of the structures, inevitably bring about decreased upkeep costs.

Furthermore, welding inspection promotes a society of high quality within companies, encouraging adherence to finest methods and continuous improvement. By incorporating inspection processes into the welding workflow, companies can improve their track record and establish themselves as leaders in quality guarantee. Finally, the significance of welding inspection depends on its capacity to secure lives, make certain architectural reliability, and support industry standards, making it an indispensable facet of welding procedures.

Secret Industry Criteria

Guaranteeing conformity with key sector criteria is essential for maintaining the high quality and security of bonded structures. Numerous companies establish these standards to promote best methods in welding and evaluation. Among the most acknowledged are the American Welding Society (AWS) and the American Culture of Mechanical Designers (ASME), which offer detailed standards and specifications for welding procedures and inspection standards.

AWS requirements, such as AWS D1.1 for structural welding, overview needs for products, design, and screening to make sure the stability of welds. In a similar way, ASME codes, consisting of ASME Area IX, govern the certification of welders and welding procedures, ensuring consistent top quality in industrial applications. Globally, the ISO 3834 common highlights high quality requirements for combination welding, offering a structure for organizations to demonstrate conformity with worldwide finest techniques.

Conformity with these criteria not only improves the dependability of bonded frameworks however also reduces dangers related to structural failings. Moreover, adherence to industry requirements is usually a requirement for regulatory authorizations and can considerably influence project specifications. Inevitably, understanding and executing these essential standards are vital for effective welding evaluation and quality guarantee.

Inspection Techniques Overview

Reliable welding examination counts on a variety of techniques created to assess the quality and integrity of welds. These techniques can be generally classified into non-destructive and devastating screening (NDT) methods. Non-destructive testing techniques, which are commonly preferred in the market, permit the analysis of welds without compromising the honesty of the material.

Among one of the most typically made use of NDT techniques are visual assessment, ultrasonic testing, radiographic testing, and magnetic fragment testing. Aesthetic examination is usually the first action in the evaluation procedure, making it possible for examiners to determine surface blemishes and examine weld important link bead accounts. Ultrasonic screening employs high-frequency acoustic waves to spot internal problems and gauge the density of welds. Radiographic screening entails the use of X-ray or gamma-ray imaging to reveal inner defects, while magnetic bit screening works for discovering surface and near-surface gaps in ferromagnetic materials.

Each technique has its own benefits and restrictions, making it necessary for assessors to choose one of the most suitable technique based upon the certain demands of the project, the materials involved, and the criticality of the welds being examined. This cautious choice supports and ensures thorough assessments security and high quality requirements in welding operations.

Common Problems and Their Effects

A complete understanding of typical problems in welds is vital for keeping architectural honesty and safety and security in bonded building and constructions. Welding issues can considerably compromise the mechanical homes of the joint, bring about failings that might jeopardize both employees and tools.

Common defects consist of porosity, which manifests as tiny gas pockets trapped in the weld metal, weakening the total structure. Splitting is another prevalent concern, commonly resulting from fast air conditioning or improper joint layout, bring about stress focus that can lead to catastrophic failings. Insufficient blend happens when the weld metal falls short to appropriately bond with the base material, creating weak factors that may result in splitting up under tons.

Various other significant problems include undercutting, where the weld grain erodes the base steel, and slag additions, which can prevent the weld's toughness. Each of these issues has details ramifications; as an example, porosity can reduce ductility, while fracturing directly influences tensile strength. Determining and recognizing these defects during evaluation is crucial for applying corrective measures and guaranteeing compliance with market requirements, eventually securing the structural stability of welded assemblies.

Ideal Practices for Quality Control

Implementing ideal practices for quality control in welding processes is crucial for attaining optimum results and lessening defects. One important method is the establishment of clear welding procedures that follow sector requirements and requirements. These procedures must include in-depth instructions regarding product selection, joint prep work, and welding strategies to make sure consistency and top quality.

Regular training and certification of welding personnel are also important. Experienced welders that comprehend the importance of quality control are more probable to produce sound welds. Additionally, executing a durable evaluation program, including both non-destructive and aesthetic testing (NDT), can help determine problems early why not check here at the same time, enabling timely corrective actions.

Paperwork plays a key function in top quality assurance. Keeping exact records of welding criteria, repair services, and evaluations guarantees traceability and find this liability. Employing sophisticated technologies such as automated welding machines can improve precision and decrease the possibility for human mistake.

Lastly, fostering a culture of high quality within the company encourages staff members to focus on quality in their job. By sticking to these best methods, companies can enhance the honesty of their welding processes, eventually resulting in improved product top quality and lowered costs associated with rework and fixings.

Verdict

In conclusion, welding inspection plays an essential duty in ensuring the integrity and safety and security of bonded frameworks. By executing finest practices, organizations can boost dependability, lessen maintenance prices, and cultivate count on amongst customers, eventually adding to successful welding operations.

Additionally, welding inspection promotes a culture of quality within organizations, motivating adherence to finest techniques and continual renovation. In verdict, the importance of welding inspection exists in its capability to safeguard lives, make sure architectural dependability, and copyright industry standards, making it an important element of welding procedures.

Amongst the most recognized are the American Welding Culture (AWS) and the American Culture of Mechanical Engineers (ASME), which provide in-depth guidelines and specs for welding processes and assessment requirements.

Ultimately, understanding and executing these key requirements are vital for effective welding examination and high quality assurance.

Efficient welding evaluation relies on a variety of strategies created to analyze the top quality and integrity of welds. - Welding Inspection Gilbert Arizona

Report this page